Solar panel cleaning - 5 tips to consider when cleaning large PV installations

Clean solar panels for the best yields - how and why to clean the solar panels: Photovoltaics continue to enjoy great popularity in Germany, especially in industry. Alongside wind power, solar energy is one of the greatest hopes of the energy transition, accounting for 23.2% of electricity generation from renewable energies. However, the great potential of the technology is also accompanied by everyday questions: How can solar panels from large systems, for example on the roof, be cleaned efficiently and safely? What photovoltaic cleaning equipment is available? We explain the dos and don'ts of automated solar panel cleaning with robots.

How often and with what should solar panels be cleaned?

In order to function optimally, it makes sense for operators of solar power systems to clean their PV modules regularly. This is because soiling such as bird droppings, grease and rust dust have a negative impact on the performance of the modules. According to the Fraunhofer Institute, soiling can significantly reduce the maximum output of a PV system. This not only reduces the yield of self-used solar energy, but also reduces the potential feed-in to the electricity grid and the corresponding remuneration. How often a system actually needs to be cleaned using conventional cleaning aids or modern PV cleaning robots depends in particular on its location and the precipitation there. Professional cleaning of solar installations is recommended at least once a year, especially in agricultural areas.

Which cleaning methods are useful for solar cleaning in industry?

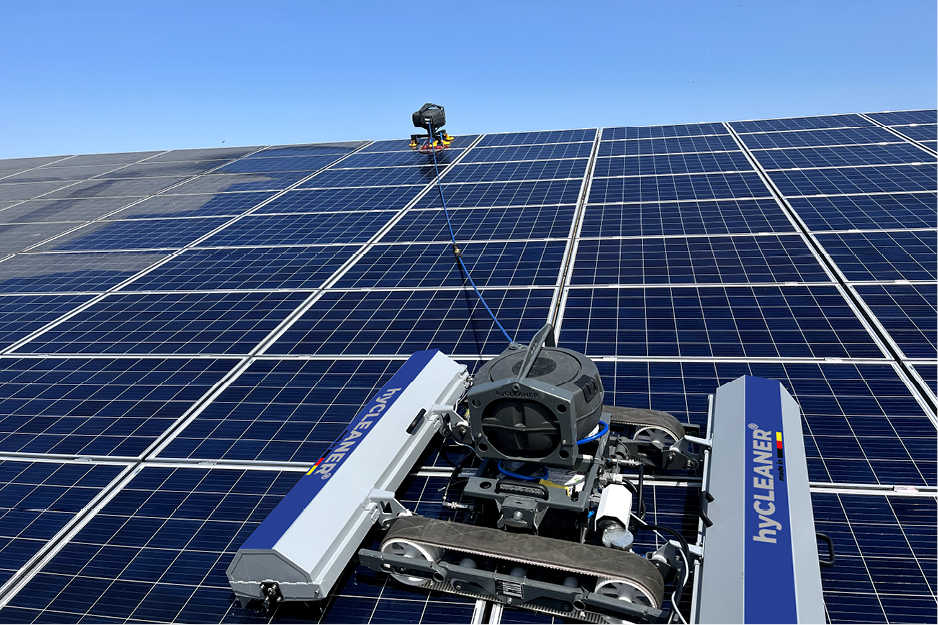

Cleaning robots are an integral part of modern facility cleaning operations. The same applies to the cleaning of large PV systems. Here, the solar cleaning robots score particularly well thanks to their high efficiency and environmental compatibility - because the high rotation of the brushes ensures an optimum cleaning effect without harmful and environmentally damaging chemicals. If you also clean with osmosis water instead of conventional water, the positive effect is maximized.

5 tips - Solar panel cleaning : how to do it right

To ensure that regular cleaning of the solar panels with the PV cleaning robot is efficient and safe, there are a few important points to bear in mind:

1. safety first: Getting the solar cleaning robot safely onto the roof

Safety is the top priority when it comes to using robots to clean PV modules on the roof. Roofs in particular have individual requirements.

As a general rule, cleaning should always be carried out by a professional using climbing aids or, ideally, ABS fall protection grids. The great advantage of solar cleaning robots - compared to manual cleaning of solar panels, e.g. with telescopic poles - is obvious: cleaning staff do not have to enter the roof at all. Once the robot has been placed on the roof and secured with ropes, it does its job safely and reliably. Experienced cleaners should always carry out a visual inspection of the parts before commissioning and switch off the solar installation for the duration of cleaning.

Good to know: The hyCLEANER solar cleaning robots are equipped with fall protection sensors . This allows the robot to recognize the end of the solar surface at an early stage and can be steered in the opposite direction for optimum cleaning of the solar panels.

Before use on the roof, a function check of the cleaning robot including edge detection, as currently only offered by hyCLEANER, is important: Watch our video here.

2. adjust the cleaning behavior of the surface and clean the solar panels correctly

Depending on how dirty an area is and how high the angle of inclination is, the cleaning behavior with the machine must be adapted. This includes roping up the robot, but it is also important to use the right driving pads. For example, it is advisable to use rubber driving pads if the area is heavily soiled with ammonia (e.g. in cowsheds).

Good to know: The hyCLEANER accessories include three different driving pads - leather, rubber or neoprene - for different applications and surface requirements. They can be easily exchanged using the Velcro fastener.

Important: Also clean the brushes of the machine and the driving pads after cleaning - this can easily be done with running water. The following applies: Never clean the machine or PV system with a high-pressure cleaner!

3. pre-cleaning: Note the grip and angle of inclination before cleaning the solar panels

Similar to snow groomers, the solar cleaning robots are driven by two chain-driven undercarriages, which give them the necessary grip on the slippery, sometimes steep surface. Similar to the rubber compound for cars in winter and summer, the hyCLEANER cleaning robot has different types of driving pads that can be easily changed using Velcro, depending on the area of application:

- one especially for dry cleaning, e.g. in desert regions

- one for normal soiling (depending on the machine model with a climbing ability of up to 25°)

- one that is specially developed for cleaning very dirty surfaces, such as cowsheds

Correct handling of the driving pads is essential to ensure the necessary grip. Pre-cleaning one or two panels before placing the robot on them is therefore always recommended (see also next point). For the best possible grip, it is also advisable to ensure that the hose is guided from above. This prevents the load from pulling downwards and making contact with the surface more difficult.

Also important: Before cleaning, the slope of the roof should be checked using a measuring device and the surface conditions correctly assessed. Depending on the model and surface condition of the area to be cleaned, the hyCLEANER cleaning robots are suitable for surfaces with slopes of up to 25° (47%).

Tip: For stubborn stains, you should soak the roof beforehand or ideally clean it after a long period of rain.

4. observe water pressure and water quantity

For maximum cleaning effect, pre-cleaning and main cleaning with water is recommended. Osmosis water is particularly suitable for both processes. The filtered water, from which salts, minerals and other impurities are removed in advance, is very gentle to clean - and yet highly effective.

To ensure gentle and successful cleaning, it is essential to use a sufficient amount of water. This is because the less water is used, the more likely it is that dirt will rub against the collector surface. This means that there is no flushing effect to loosen the dirt, meaning that the same areas have to be cleaned several times.

Solar robots work with low pressure. This means they don't need that much water pressure. Two to four bar is sufficient - this corresponds to the amount that comes out of the tap. Nevertheless, there are pressure losses associated with the hose diameter and working at height. As a rule of thumb, you lose 1 bar of water pressure for every 10 meters of height.

The diameter of the hose is just as important as the correct water pressure. It must be large enough to pump enough water into the robot. With the solarROBOT series from hyCLEANER, it is important to use supply hoses with an internal diameter of at least 10 mm.

Important: Under no circumstances should high-pressure cleaners be used for cleaning, as the high water pressure also damages the sensitive surface.

Cleaning PV modules with water: Did you know that robots use much less water than conventional high-pressure cleaners? At approx. 0.5 liters/m², that's up to 10 times less water per square meter.

5. take proper care of the battery

To ensure the longevity of the cleaning robot, you should recharge the battery from time to time, especially during the cleaning-free winter months. Similar to an e-bike, so-called "battery jogging" is important to ensure that the battery maintains its performance. What does that mean? It should be used regularly.

Robots revolutionize the professional cleaning of solar panels

The use of solar panels on roofs is not only gaining momentum in the agricultural sector. However, in order for the systems to function optimally and generate good yields, operators must maintain and clean them regularly - an attractive opportunity for professional cleaning companies and solar panel operators who take over the cleaning of their PV system themselves. Cleaning robots that clean solar panels safely and efficiently have proven themselves in use. Anyone who pays attention to the above points and pays attention to safety, cleaning basics such as water pressure, water quantity and machine care, as well as the roof condition and battery check, is ready for a lucrative solar season.

Frequently asked questions about solar panel cleaning

Cleaning solar panels with glass cleaner: does it make sense?

Chemical cleaning agents are harmful to the environment and health, cause costs and are comparable to other cleaning methods in terms of efficiency. Cleaning solar panels with glass cleaner is therefore not recommended.

Osmosis purification works at least as efficiently. Using special filter technology, a PV system can be cleaned with treated tap water. This makes it harmless to the environment and health compared to chemical agents and very cost-effective to operate.

Can you clean photovoltaics with rainwater?

Yes, rainwater can indeed be an effective and environmentally friendly way to clean solar panels during the year, especially if it falls in sufficient quantity and intensity to naturally wash away dust and other debris. In many cases, rain can reduce or delay the need for manual cleaning, especially in regions with frequent rainfall. While rainwater can be helpful for cleaning solar panels, it is important to inspect the solar panels regularly and perform a mechanical cleaning at least once a year.

Would you like to learn more about our PV panel cleaning robots? Then contact us. We will be happy to advise you!